Southwest Machine Technologies: Precision Equipment for Texas Fabrication

Texas factory activity posted its strongest expansion signal in months during January 2026, marking a dramatic reversal from December’s contraction. The Federal Reserve Bank of Dallas reported the production index surged to 11.2 from negative 3.0—a swing of more than 14 points that signals renewed momentum across the state’s industrial base. For fabrication shops navigating this rebound, fiber laser cutting systems have emerged as the technology enabling manufacturers to capitalize on returning demand without the workforce expansion that remains stubbornly difficult.

The Dallas Fed’s Texas Manufacturing Outlook Survey captured this sentiment directly from business executives. New orders jumped 18 points to 11.8, while capacity utilization climbed 12 points to 7.1. One machinery manufacturer responding to the survey described conditions bluntly: “Business is booming. We are buying new equipment to increase production, since we are falling behind on our inventory requirements.”

This equipment investment surge reflects a broader transformation in how Texas manufacturers approach production capacity. Rather than competing for scarce skilled workers in a market where 79 percent of manufacturing executives cite labor shortages as their greatest challenge, shops are investing in automation technologies that multiply the output of existing teams. Fiber laser systems sit at the center of this strategy.

The Technology Advantage Driving Investment

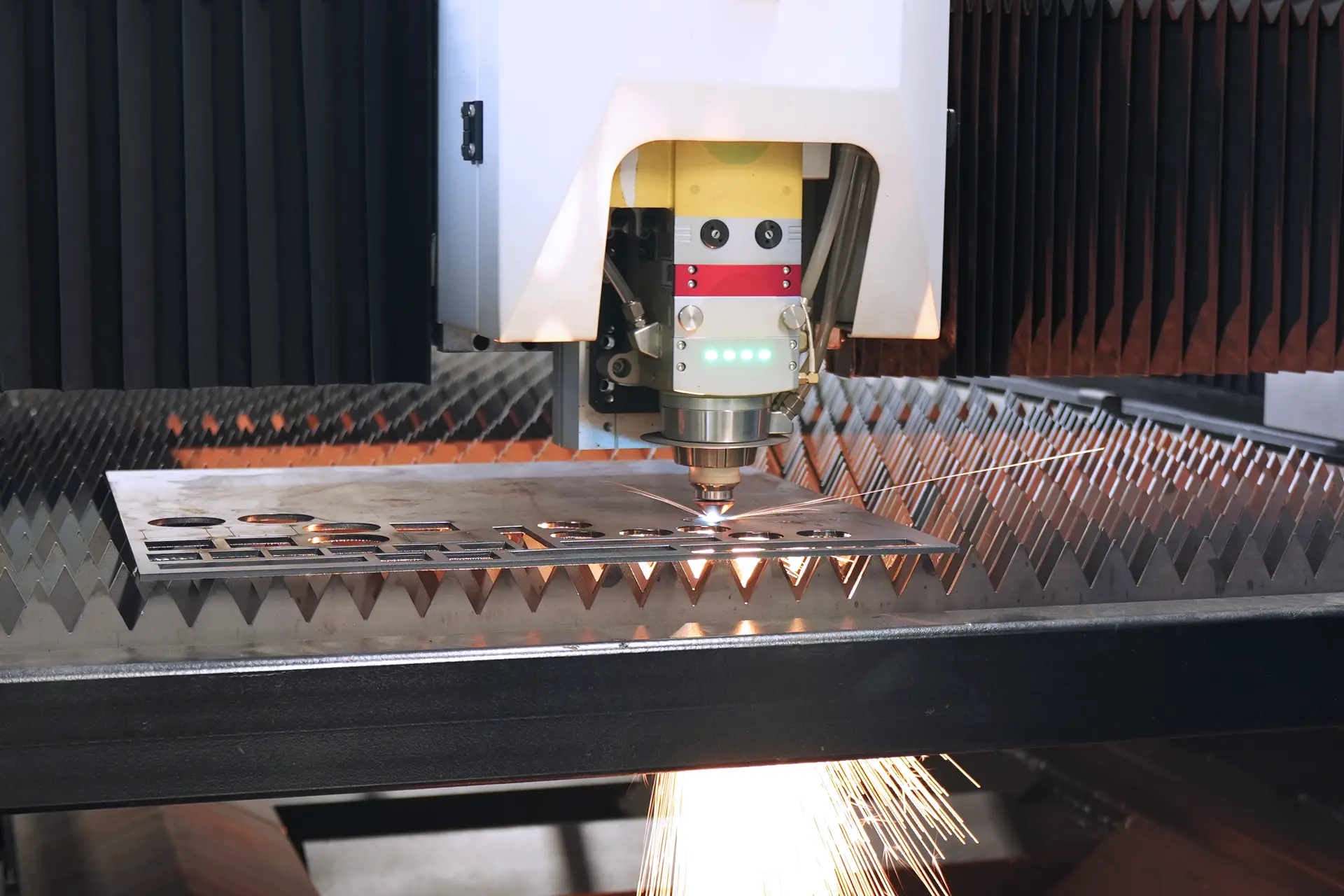

Fiber laser cutting machines deliver performance characteristics that make them particularly valuable during a manufacturing recovery. Unlike traditional CO2 laser systems, fiber technology converts electrical power to cutting energy at efficiencies between 20 and 30 percent—roughly three to four times better than CO2 alternatives. This efficiency translates directly to lower operating costs at precisely the moment when inflation and rising energy prices pressure margins.

The productivity gains extend beyond energy savings. Modern fiber laser systems routinely cut sheet metal three to five times faster than CO2 lasers, depending on material type and thickness. For a fabrication shop responding to the order surge the Dallas Fed documented, this speed advantage means the difference between capturing new business and turning away profitable work.

Processing capability further distinguishes fiber technology in the current market. Fabrication shops serving Texas industries from oil and gas to construction frequently work with reflective metals including aluminum, brass, and copper. Fiber lasers handle these materials that historically challenged CO2 systems, expanding the range of work shops can accept without specialized equipment changes. The U.S. Bureau of Labor Statistics manufacturing sector data shows fabricated metal product manufacturing remains among the largest manufacturing subsectors, with establishments increasingly requiring versatile cutting capability to serve diverse customer requirements.

Regional Dynamics Favoring Texas Fabricators

Texas manufacturers operate from an advantageous position as the national manufacturing landscape shifts. The state has claimed the Governor’s Cup award for job-creating relocation and expansion projects for thirteen consecutive years. The Texas Economic Development Corporation notes the state’s GDP now exceeds 2.6 trillion dollars—making it the eighth-largest economy globally if ranked as an independent nation.

This economic scale creates sustained demand for fabricated components across sectors from energy infrastructure to commercial construction. The Dallas Fed survey captured specific market opportunities: health care facility construction and data center projects are offsetting slowdowns in commercial office work, while new home construction projections point toward increased demand in the second half of 2026.

For fabrication shops positioned with modern fiber laser capability, understanding how to address the labor constraints that accompany growth becomes essential. Exploring How Texas Fabrication Shops Are Solving the Skilled Worker Shortage with Automation provides critical context for manufacturers balancing capacity expansion against workforce realities.

The investment patterns visible across Texas mirror broader industry trends. The global fiber laser market reached nearly 6.9 billion dollars in 2024 and projects growth at 11.1 percent annually through 2033. Manufacturing equipment suppliers report that automated laser cutting lines improve production throughput by 45 percent while reducing material waste by 18 percent through AI-powered nesting software.

What the Data Signals for Fabricators

The January manufacturing survey results require careful interpretation. While headline numbers signal expansion, business executives also expressed substantial uncertainty about conditions six months forward. Tariff policies, international trade dynamics, and the uneven recovery across manufacturing subsectors create planning challenges that sophisticated equipment investments can help address.

Fabricators who invested in fiber laser technology during previous cycles report advantages that compound during uncertain periods. The flexibility to process diverse materials means shops can pivot toward growing market segments—whether data center components, renewable energy infrastructure, or precision parts for the aerospace supply chain expanding across Texas.

Production economics favor modern fiber systems regardless of which specific sectors drive demand. Energy consumption that runs 30 to 40 percent below CO2 alternatives protects margins as utility costs fluctuate. Minimal maintenance requirements compared to gas-based laser systems reduce both direct costs and production interruptions that complicate delivery commitments.

Manufacturers evaluating fiber laser technology should understand the specific performance characteristics that differentiate available systems. Reading Fiber Laser vs. CO2: Which Cutting Technology Fits Your Texas Shop? provides technical comparison data essential for informed equipment decisions.

SWMT: Your Texas Partner for Fabrication Equipment

Southwest Machine Technologies provides fiber laser cutting systems from Dener USA engineered specifically for the demands Texas fabricators face. From sheet laser systems processing materials up to 20kW capacity to tube laser machines handling profiles up to 40 feet, SWMT delivers equipment matched to your production requirements.

Our Services Include:

- Fiber Laser Systems – Sheet and tube laser cutting machines with power options from 3kW to 20kW

- CNC Machine Tools – Complete milling and turning solutions for Texas manufacturing

Ready to Capitalize on the Texas Manufacturing Rebound? Contact SWMT to discuss how fiber laser technology can position your shop for growth.

Works Cited

“Growth Resumes in Texas Manufacturing.” Texas Manufacturing Outlook Survey, Federal Reserve Bank of Dallas, 26 Jan. 2026, www.dallasfed.org/research/surveys/tmos/2026/2601. Accessed 30 Jan. 2026.

“Manufacturing: NAICS 31-33.” Industries at a Glance, U.S. Bureau of Labor Statistics, www.bls.gov/iag/tgs/iag31-33.htm. Accessed 30 Jan. 2026.

Related Articles

- How Texas Fabrication Shops Are Solving the Skilled Worker Shortage with Automation

- Fiber Laser vs. CO2: Which Cutting Technology Fits Your Texas Shop?