Austin’s manufacturing landscape has undergone dramatic transformation as the city establishes itself as a major hub for precision manufacturing and advanced technology production. The region’s diverse industrial base creates substantial demand for sophisticated turning operations capable of producing high-precision cylindrical components. From aerospace components to medical devices, Austin manufacturers require turning solutions that deliver exceptional accuracy and reliability.

Southwest Machine Technologies provides comprehensive CNC turning machine solutions specifically designed for Austin-area manufacturers seeking to enhance their precision turning capabilities. Our advanced turning systems enable local businesses to meet the demanding requirements of modern manufacturing while maintaining competitive production costs.

Medical Device Industry Precision Requirements

Austin’s rapidly expanding medical device sector demands exceptional precision in turned components used for surgical instruments, implants, and diagnostic equipment. Modern medical applications require surface finishes measured in microinches and dimensional tolerances that exceed conventional manufacturing capabilities. CNC turning machines provide the precision and repeatability needed for FDA-regulated manufacturing environments.

Biocompatible materials including titanium alloys, stainless steel grades, and specialized polymers present unique machining challenges that advanced turning systems address through specialized cutting strategies. Temperature control becomes critical when machining materials that must maintain their metallurgical properties for medical applications. Contamination prevention requires enclosed machining environments and specialized coolant systems.

Aerospace Component Manufacturing Excellence

Central Texas aerospace manufacturers rely on precision turning operations for producing critical flight components including landing gear bushings, hydraulic system components, and engine parts. These applications demand exceptional accuracy and surface finish quality that can only be achieved with advanced CNC turning technology. Aerospace materials including Inconel, Waspaloy, and specialized titanium alloys require precise cutting parameters and tool selection.

Aerospace manufacturing requires comprehensive documentation and traceability that modern turning centers provide through integrated quality control systems. Process monitoring capabilities ensure that machining parameters remain within specification throughout production runs. Advanced turning systems enable single-setup machining of complex aerospace components that would otherwise require multiple operations.

Technology Sector Precision Components

Austin’s thriving technology industry creates significant demand for precision-turned components used in semiconductor manufacturing equipment, data center hardware, and consumer electronics. High-volume production requirements combined with tight tolerances make CNC turning the optimal manufacturing approach for cylindrical technology components. Heat sink production, connector manufacturing, and housing components require the precision that modern turning centers deliver.

Rapid prototyping capabilities enable technology companies to accelerate product development cycles through quick-turn manufacturing of prototype components. Why CNC turning is essential for manufacturing in Texas demonstrates how advanced turning operations support innovation in Austin’s technology sector.

Automotive Industry Applications

Austin’s automotive manufacturing sector utilizes precision turning operations for producing engine components, transmission parts, and suspension system elements. High-volume automotive applications require consistent part quality across thousands of components while maintaining competitive production costs. Modern turning centers provide the productivity and reliability needed for automotive manufacturing schedules.

Electric vehicle component production presents new challenges including lightweight materials and complex geometries that require specialized turning techniques. Battery system components, motor housings, and charging system parts demand precision turning capabilities that can handle diverse material requirements. Advanced turning systems adapt automatically to different materials and cutting conditions.

Energy Sector Manufacturing Demands

Texas energy companies require precision-turned components for oil and gas exploration equipment, renewable energy systems, and power generation applications. Harsh operating environments demand components with exceptional reliability and resistance to corrosion and wear. CNC turning operations produce valve components, pump parts, and drilling equipment elements that meet these demanding requirements.

Renewable energy applications including wind turbine components and solar tracking systems require precision turning of large-diameter components with tight tolerances. Advanced turning centers provide the capacity and accuracy needed for these specialized applications. Material diversity in energy applications requires flexible turning systems capable of handling everything from aluminum to exotic superalloys.

Advanced Turning Center Capabilities

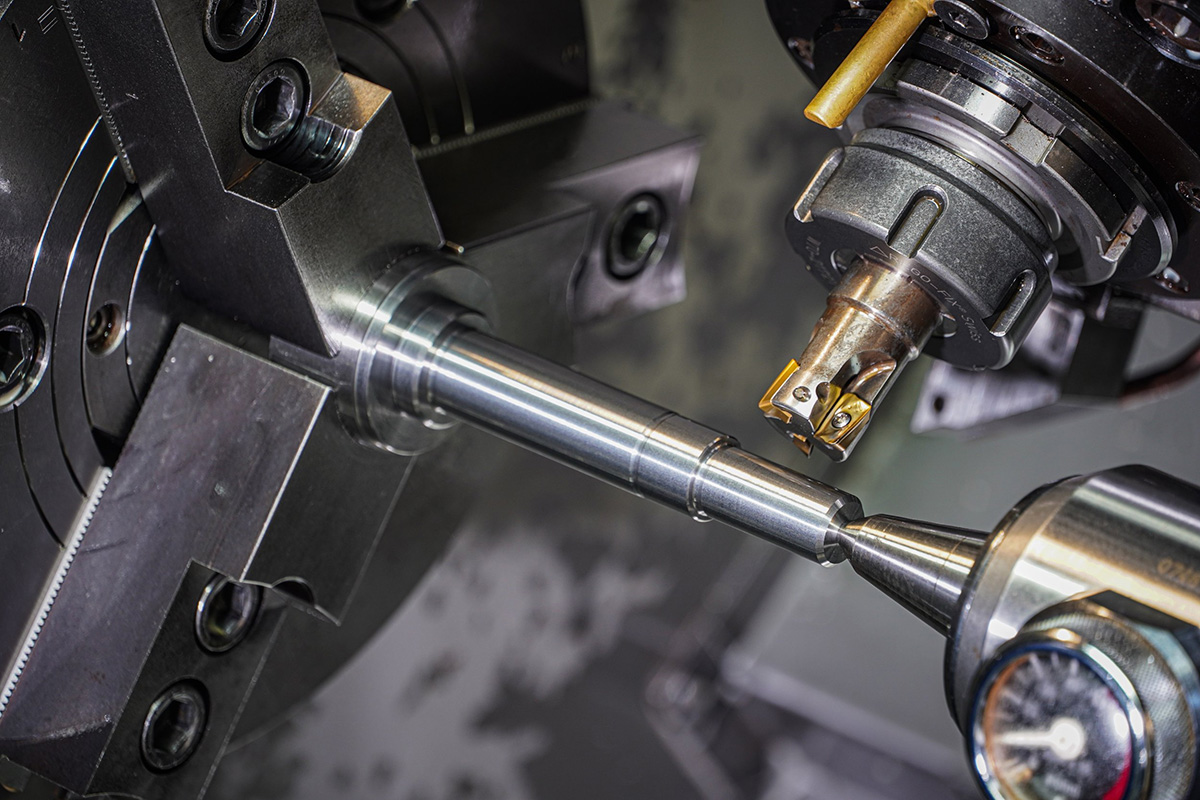

Modern CNC turning centers incorporate multiple axes of motion that enable complex part geometries to be machined in single setups. Live tooling capabilities combine turning and milling operations in single machines, reducing setup times and improving part accuracy. Sub-spindle systems enable complete part machining without manual repositioning, maximizing productivity and precision.

Y-axis capability extends turning center versatility by enabling off-centerline machining operations. This capability allows manufacturers to produce complex parts with holes, slots, and other features that would otherwise require secondary operations. Advanced turning centers can machine complete parts from bar stock with minimal manual intervention.

Precision Spindle Technology

Turning center spindles require exceptional accuracy and power to handle diverse machining applications. High-speed spindles enable efficient machining of aluminum and other non-ferrous materials while maintaining the torque needed for steel and superalloy applications. Spindle bearing technology directly impacts part accuracy and surface finish quality.

Spindle thermal management prevents accuracy degradation during extended production runs. Advanced cooling systems maintain spindle temperature within narrow ranges that preserve dimensional accuracy. Spindle monitoring systems track performance parameters and alert operators to potential maintenance requirements before problems develop.

Workholding Innovation and Flexibility

Effective workholding is fundamental to achieving precision and productivity in turning operations. Hydraulic chuck systems provide uniform clamping pressure that prevents part distortion during machining. Collet systems offer superior concentricity for precision applications while enabling rapid part changeover.

Bar feeding systems enable lights-out manufacturing by automatically feeding material to turning centers without operator intervention. These systems maximize machine utilization while maintaining consistent part quality. Advanced bar feeding systems include material handling capabilities for diverse bar sizes and lengths.

Quality Control Integration

In-process measurement systems provide real-time feedback on part dimensions during machining operations. Touch probe systems enable automatic part setup and dimensional verification without removing components from the turning center. Laser measurement systems provide non-contact inspection of complex geometries and delicate surfaces.

Statistical process control systems monitor turning parameters and part quality to identify trends that could indicate potential problems. Enhancing efficiency tips for effective CNC turning in Texas explains how integrated quality control systems improve manufacturing efficiency and reduce scrap rates.

Advanced Control Systems and Programming

Modern turning centers feature sophisticated CNC control systems with intuitive programming interfaces. Conversational programming capabilities enable operators to create complex part programs without extensive G-code knowledge. 3D simulation and verification prevent programming errors that could damage cutting tools or workpieces.

Adaptive control systems automatically adjust cutting parameters based on real-time feedback from the machining process. These systems optimize tool life and surface finish quality while preventing tool breakage and part defects. Machine learning capabilities enable turning centers to improve performance automatically over time.

Cutting Tool Technology Optimization

Turning operations require specialized cutting tools designed for specific materials and applications. Carbide inserts with advanced coatings provide superior performance in steel and cast iron applications. Ceramic and cermet tools enable high-speed machining of difficult materials including hardened steels and superalloys.

Tool management systems track cutting tool usage and predict when tool changes are required. Automatic tool measurement systems verify tool dimensions and detect wear before it affects part quality. Optimized tool selection and cutting parameters maximize productivity while minimizing tooling costs.

Automation and Robotic Integration

Modern manufacturing operations demand automation systems that maximize equipment utilization and reduce labor costs. Robotic part handling systems integrate with turning centers to provide automated loading and unloading capabilities. These systems enable lights-out manufacturing operations that continue production during non-working hours.

Part sorting and packaging systems integrate with turning operations to provide complete automation from raw material to finished components. Quality control integration ensures that only acceptable parts proceed to packaging and shipment. Automated systems reduce labor costs while improving consistency and productivity.

Material Handling and Chip Management

Efficient material handling systems maximize turning center productivity by minimizing non-productive time. Automatic bar feeders handle material supply while chip conveyors remove machining waste continuously. Proper chip management prevents coolant contamination and reduces maintenance requirements.

Coolant filtration systems maintain cutting fluid quality and extend coolant life significantly. High-pressure coolant delivery improves chip evacuation and extends cutting tool life. Mist collection systems maintain clean working environments and comply with environmental regulations.

Energy Efficiency and Environmental Considerations

Advanced turning centers incorporate energy-efficient technologies that reduce power consumption and environmental impact. Variable frequency drives optimize motor operation based on actual load requirements. Standby modes reduce energy consumption during idle periods while maintaining rapid restart capabilities.

Minimum quantity lubrication systems reduce coolant usage dramatically while maintaining cutting performance. These systems eliminate coolant disposal costs and reduce environmental impact. Energy monitoring systems track power consumption and identify optimization opportunities that reduce operating costs.

Training and Technical Support

Successful turning center implementation requires comprehensive training and ongoing technical support. Operator training programs cover machine operation, programming techniques, and basic maintenance procedures. Advanced training includes optimization techniques and troubleshooting procedures that maximize equipment effectiveness.

Technical support services include remote diagnostics capabilities that enable rapid problem resolution. On-site service support ensures minimal production disruption when maintenance or repairs are required. Parts availability programs maintain adequate inventory to support continuous operation.

Return on Investment Analysis

CNC turning centers deliver measurable return on investment through increased productivity, improved part quality, and reduced operating costs. Higher spindle speeds and advanced tooling reduce cycle times compared to conventional turning operations. Automation capabilities enable extended unmanned operation that maximizes machine utilization rates.

Reduced setup times and improved first-pass quality eliminate costly rework and material waste. Energy efficiency improvements and reduced coolant consumption lower operating costs over the equipment’s operational life. Predictive maintenance capabilities prevent expensive breakdowns and extend equipment life.

Future Technology Integration

Emerging technologies including artificial intelligence and machine learning are being integrated into turning operations to optimize performance automatically. Smart manufacturing systems learn from production data to continuously improve machining efficiency and part quality. Internet of Things connectivity enables remote monitoring and predictive maintenance capabilities.

Additive manufacturing integration enables hybrid processes that combine turning with 3D printing capabilities. These technologies allow manufacturers to produce complex parts that combine conventional machining precision with additive manufacturing flexibility. Future turning systems will incorporate multiple manufacturing processes in integrated platforms.

Ready to enhance your Austin manufacturing capabilities with advanced CNC turning technology? Contact our turning specialists today to discover how modern turning solutions can transform your production operations and deliver superior precision components.

Industry Standards and Compliance Resources

Manufacturing operations must comply with comprehensive industry standards and safety regulations. The Environmental Protection Agency (EPA) provides guidelines for metalworking fluid management and waste disposal that are essential for turning operations. These regulations ensure environmental compliance and worker safety in precision manufacturing environments.

The Food and Drug Administration (FDA) establishes manufacturing standards for medical device components that require precision turning operations. FDA regulations provide comprehensive guidance for quality control systems and documentation requirements that are critical for medical device manufacturing compliance.

Frequently Asked Questions

What types of components are best suited for CNC turning operations in Austin manufacturing?

CNC turning operations excel in producing cylindrical components with complex geometries including shafts, bushings, pins, and threaded parts used across diverse Austin industries. Medical device applications benefit from turning operations that produce surgical instrument components, implant parts, and diagnostic equipment elements requiring exceptional surface finishes and dimensional accuracy. Aerospace manufacturers utilize turning for landing gear components, hydraulic system parts, and engine elements that demand tight tolerances and specialized materials. Technology sector components including heat sinks, connector bodies, and housing elements require the precision and productivity that modern turning centers provide. Automotive applications include engine components, transmission parts, and suspension elements that require high-volume production with consistent quality.

How do modern turning centers handle the diverse materials used in Austin manufacturing?

Advanced CNC turning centers accommodate diverse materials through adaptive machining strategies and specialized cutting tool technology. Aluminum alloys common in aerospace and technology applications machine efficiently at high speeds using sharp carbide tools and flood coolant systems. Stainless steel grades used in medical devices require moderate speeds with positive rake angle tools and high-pressure coolant delivery. Titanium alloys machine best with ceramic or carbide tools at lower speeds with constant surface speed control. Hardened steels used in automotive applications benefit from cubic boron nitride tools and rigid machine construction. Advanced control systems automatically adjust cutting parameters including spindle speed, feed rate, and coolant flow based on material properties and part geometry requirements.

What automation capabilities make turning centers suitable for lights-out manufacturing?

Modern turning centers include comprehensive automation features that enable extended unmanned operation in Austin manufacturing facilities. Bar feeding systems automatically supply material to turning centers without operator intervention, enabling continuous production from bar stock. Robotic part handling systems provide flexible loading and unloading capabilities for complex part geometries and varying production volumes. Tool management systems automatically change cutting tools based on programmed sequences and tool life monitoring. Quality control integration includes in-process measurement systems that verify part dimensions and automatically adjust processes when variations are detected. Chip management systems including conveyors and coolant filtration maintain clean operating conditions during extended production runs.

How do turning centers maintain precision across high-volume production runs?

Precision maintenance during high-volume production requires multiple advanced technologies working together continuously. Thermal compensation systems automatically adjust for machine expansion and thermal growth that occurs during extended operation, maintaining positioning accuracy regardless of temperature variations. Spindle bearing systems utilize precision rolling elements and advanced lubrication systems that maintain accuracy over millions of revolutions. Real-time monitoring systems track cutting forces, vibration levels, and dimensional accuracy to identify potential problems before they affect part quality. Tool wear monitoring systems predict when cutting tools require replacement based on actual cutting conditions rather than predetermined schedules. Statistical process control systems continuously monitor part dimensions and automatically adjust cutting parameters to maintain tolerances throughout production runs.

What training and support services are available for turning center implementation?

Comprehensive training and support services ensure successful turning center implementation in Austin manufacturing operations. Operator training includes hands-on instruction in machine setup, programming techniques, and troubleshooting procedures specific to turning applications. Programming training covers advanced features including live tooling, sub-spindle operation, and multi-axis capabilities. Maintenance training provides instruction in preventive maintenance procedures, cutting tool selection, and basic troubleshooting techniques that maximize equipment uptime. Technical support services include remote diagnostics capabilities that enable rapid problem resolution through internet connectivity. On-site service support provides immediate assistance when complex problems require hands-on troubleshooting. Parts availability programs ensure critical components are readily available to minimize production disruptions during maintenance procedures.